- Home

- Products

- Prefabricated House

- Prefabricated houses

Prefabricated houses

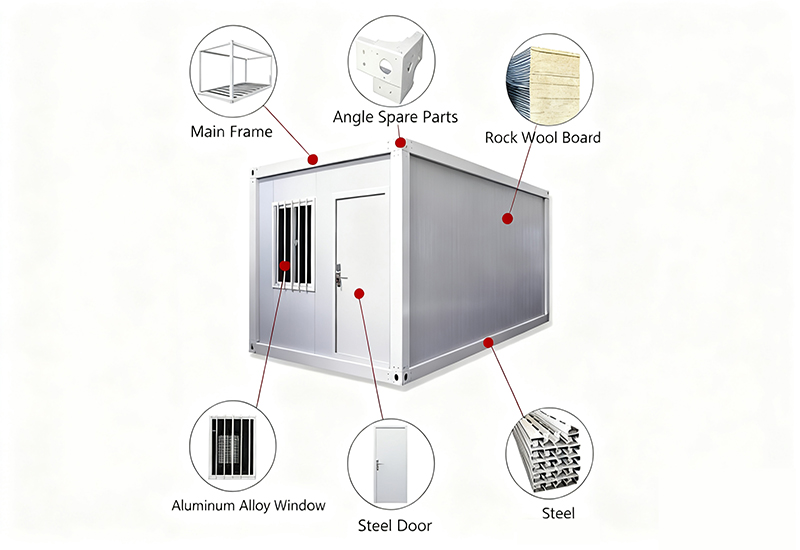

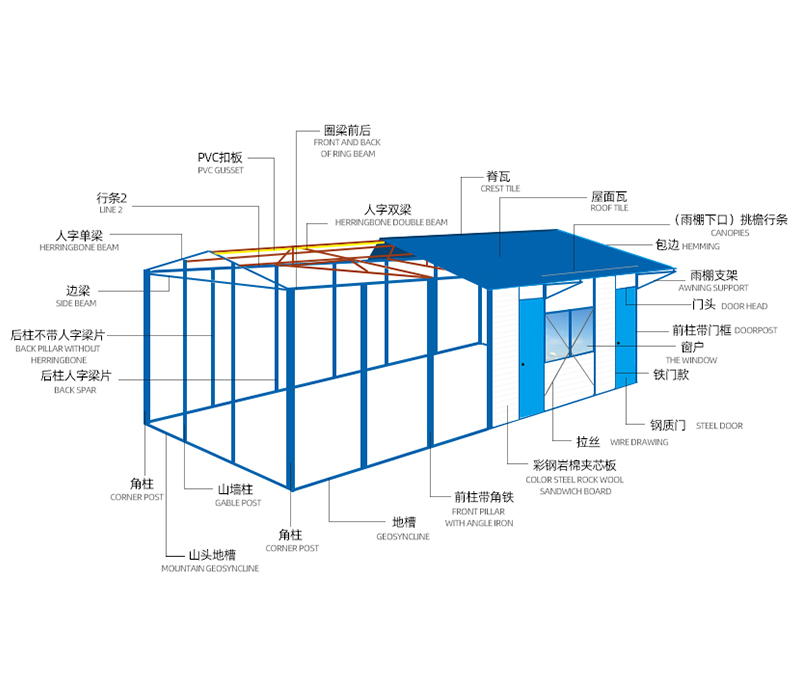

Prefabricated houses are modular prefabricated buildings with light steel structures as frames and sandwich panels as enclosure materials. They have core advantages such as convenient installation, economical cost, mobility and recyclability, and flexible adaptability.

They are widely used in temporary offices, construction site dormitories, emergency resettlement, temporary shops, post-disaster reconstruction and other scenarios, and are an efficient and practical temporary/semi-permanent building solution in the construction industry.

They are widely used in temporary offices, construction site dormitories, emergency resettlement, temporary shops, post-disaster reconstruction and other scenarios, and are an efficient and practical temporary/semi-permanent building solution in the construction industry.

-

Their core features can be summarized as follows:

Lightweight Structure and Efficient Installation:Utilizing factory-prefabricated components (frame, wall panels, roof, etc.), on-site installation requires only bolting or hoisting. A single unit (30-50㎡) can be completed in 1-3 days, significantly shortening the construction cycle and reducing labor costs.

-

Controllable Cost and High Cost-Effectiveness:

Primarily using light steel structures and color steel sandwich panels (rock wool, polystyrene, etc. as core materials), the cost is only 30%-50% of traditional brick-concrete buildings. Furthermore, maintenance is simple, requiring no complex daily upkeep.

-

Flexible and adaptable to diverse scenarios:

Custom sizes are available to meet specific needs (single-room, multi-room, multi-story combinations), with individual unit sizes ranging from 10㎡ to hundreds of㎡. These can serve as single dormitories, small offices, or be combined to form large spaces such as dormitories, project offices, and temporary schools.

-

Movable and recyclable:

Components are disassembled and reused. If relocation is required, the entire unit can be hoisted and transported or disassembled and rebuilt in another location. This design is environmentally friendly, reduces construction waste, and aligns with green building trends.

-

Reliable performance and adaptable to various environments:

Sandwich panels provide insulation, heat insulation, fire resistance, and moisture resistance (rock wool core material achieves a fire rating of Class A). The lightweight steel structure, after anti-corrosion treatment, has a service life of 10-20 years, making it suitable for complex environments such as construction sites, the field, and disaster areas.

| Dimension: | L6160*W3640*H2800 |

| Wall Panels | 50mm double-sided color steel sandwich panel,

steel plate thickness 0.3mm |

| Roofing panels | 50mm double-sided color steel sandwich panel,

steel plate thickness 0.3mm |

| Main Frame | C-Shaped Galvanized Steel Channel |

| Suspended Ceiling | Gypsum board ceiling |

| Floor | Cement fiberboard |

| Door | Steel Security Doors |

| Window | Aluminum alloy sliding window |

| Color | Blue |

Latest News

Updates on solar energy storage transforming our world.

Our Services

Our Services

Contact Us

Get personalized prefabricated houses and container houses advice.